A little about the Screamin' Eagle Delphi mapping software

EFI Tuner Kit

The Screamin' Eagle mapping software has a 'Basic' and an 'Advanced' Mapping Mode as well as a Data Mode program for recording and a very complete PDF operators manual. It also comes with a cable and a module that locks on to the ECU serial number for life, the first time it is used. After that, you may re-map your ECU as often as you like.

The Delphi fuel injection system calculates the injector time required to achieve an air/fuel ratio called out by the main map. The calculation is based on volumetric efficiency values entered into the front and rear cylinder maps.

The 'Basic' mode maps both cylinders via the Main map which uses Manifold Air Pressure and RPM. Even though you can view the MAP sensor values couldn't hold to those values though a full test, it's about useless.

The 'Advanced' mode has the same main map parameters (manifold air pressure and RPM) as the Basic mode, but uses front and rear maps with throttle position and RPM.

This brings up an interesting quirk of the first version of the system. There was no way to view any of the system parameters in real time!

That has been fixed in the second version.

One other feature that has the potential to be quite valuable is the ion-sensing anti-knock. When properly calibrated it will retard the timing when a cylinder approaches detonation. With the first 3 or 4 bikes I did, the anti-knock worked wonderfully, allowing the timing to be set at a value that produced the best power.

However, on two bikes (since I started using the 'A' suffix version of the program) the anti-knock would kick in and kill a pile of power. I retarded the timing until the engine lost a bunch of power, and it still activated.

I was informed that the second version had two files that had improper anti-knock parameters, so I must have chosen one or both of them.

H-D's 'Screamin' Eagle' EFI Tuner Kit support division sent me a file that, supposedly, had this fixed. I spent 2.5 hours changing the maps to the ones that I had developed for the customer and when I up-loaded it to the bike, the anti-knock kicked in and killed almost 20 HP!!???!!!

Unfortunately, for internal political reasons the anti-knock sensitivity can't be changed on the original file which I created for the bike.

Until they get that fixed, that particular feature has questionable effectiveness.

Data Mode

The Data Mode offers the ability to save system data for an hour or more. The manual offers extensive coverage of the techniques for using this capability.

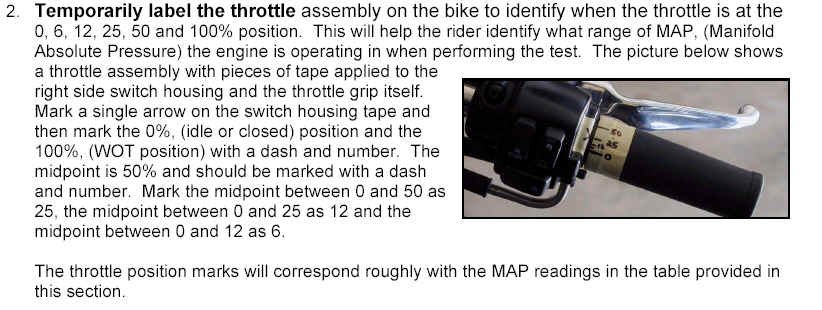

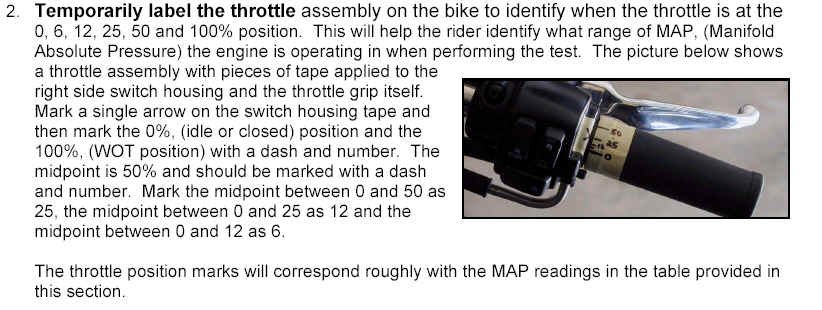

Even though the very complete PDF manual tells you to hold the throttle at different positions while taking data in the data mode, they offered no better suggestion of how to mark the throttle other than the following.

Now (after agreeing with the disclaimer) you can view the throttle position and mark it accurately for testing.

Both the data and mapping modes work well and the results (when properly done) are excellent.

I've learned to use 3-D fuel maps as a visual confirmation that the fuel data is believable. The point at 1250RPM and 60% throttle on the front cylinder map below, could probably be mashed down. It looks like I didn't get there during the mapping. High throttle and low RPM, and low throttle and high RPM, are parts of the map that aren't very important, so I'm not too worried.

The reason I've shown the map from the WOT end is to point out WOT fuel curve. The torque curve is a result of the volumetric efficiency curve. Since the engine needs the greatest amount of fuel when it takes the greatest amount of air, the fuel curve should follow the torque curve.

Even though we can't separate the torque curve of the two cylinders, when can compare the two through their fuel maps.

Below are the front and rear cylinder fuel maps for the Twin-cam 'B' motor with Rinehart pipes.

The A/F ratio of both cylinders has been adjusted to be flat, that is, the same bottom to top. Because of that, the fuel curve matches the torque curve.

Notice that the torque peaks at 4000 and drops sharply to 5000 on the front cylinder map. The trough occurs between 2750 and 3000.

The map for the rear cylinder (below) shows the torque peak to be a little higher than for the front, at 4250 and the trough is higher also at 3000 to 3500.

The difference seems to be in keeping with the longer front pipe of this system tuning at a lower RPM.

The shift of these two cylinders means that the trough isn't as pronounced as it might be with both tuning the same.

I don't have any runs that have a complete WOT power curve from 2000 RPM (that's lugging, and that's bad) but below you can see the end of that 2750-3000 RPM torque trough.