Mapping a Custom Built, One-Off, Big Motor, Fuel Injected Harley

Internet forums are a valuable information-sharing resource. The MSN, Harley Tech Talk forum is one of those.

'where can I get a good starting point map for my latest build?'

One common question is 'where can I get a good starting point map for my latest build?'

Since I believe that the best fuel injection calibration for any bike is the one that has just been created, the short answer must be; 'there isn't one.'

The Long Answer

Of course, there is a long answer, so life with your new engine doesn't look too bleak.

First, you have to have a good fuel injection mapping solution. There are three solutions that I have used.

1) Screamin' Eagle (S-E) EFI Race Tuner Kit is the first and offers all the adjustments you need.

2) TechnoResearch has DirectLink, which has all the adjustments plus, a couple different features.

3) Dynajet PCIII USB, utilizing the advanced separate cylinder mapping feature.

(I'm a proponent of separate cylinder mapping, you can read more about that in my 'Turn On the Lights' article, here; Turn On The Lights )

Second, a dynamometer with an exhaust gas analyzer will make your life a lot easier.

In spite of the recommendations in the S-E tuning manual, creating a map 'seat-of-the-pants' promises to take nearly forever, while a dyno/gas analyzer can shorten that process to a day.

Third, you'll need patience, imagination, and and a willingness to accept failure as part of any learning experience.

A lot of mechanics are short of patience and imagination. Both of these traits are good for learning, but bad for making a living.

Humans in general are failure-averse, but since you're just dealing with a machine, you don't need to worry about making a wrong decision.

It ain't brain surgery y'know!

The Victim

Greg Hegwood owned a V-Rod in 2003, and had me map/tune it using the EFI RT Kit.

His next project was going to be a Dyna Superglide Sport with a big engine. He called me about building it, but I don't do Harley engine building, so I suggested he contact Bob Wright who is R&D Performance.

The engine project came together with the following components;

S&S 'Twin-Cam' cases.

Axtell 4.125" bore cylinders and pistons.

4.625" stroke crank.

Zippers billet big-bore heads, with 2.00" inlet valves and 1.625" exhaust valves. These aren't their latest 'big valve' offering, so they would be inlet valve size limited.

A couple cams were considered. Finally, Mike Roland offered a TC6G cam which is ideally suited to a large, inlet restricted engine.

Since Greg was going for some HP, Mike offered a prototype 57mm throttle body.

A large diameter exhaust would be needed, so Greg acquired an R&B LSR 2-into-1 exhaust.

I punched the numbers into my injector calculating spreadsheet and came up with the only choice for larger Weber 'Pico' injectors, IWP 069. I acquired them from Pierce Manifolds, the U.S. distributor.

After the engine was completed and the chassis modifications were complete, there were a few details that Bob needed to attended to.

Below is a photo of Greg's bike.

During this time, Greg contacted all the suppliers, R&B, Axtell, and Zippers and began to worry about 'break-in'. Apparently, the Axtell pistons can have ring land problems if over-heated during break-in.

Everyone seemed to be concerned about break-in on the dyno. Since there isn't a chance in hell that anyone would have an EFI Race Tuner calibration for this thing, what choice is there?

A) You could run it for 1000 miles with huge injectors and the stock map, but you might only get 100 miles on a set of plugs, and contaminate your oil with gas (would that be called 'goil'?)

OR

B) You could put it on the dyno and start creating the map from the bottom (low throttle settings) up. Then you would only have a few seconds at any throttle position with improper air-fuel ratio. Plus, you'd be heat cycling the thing a dozen times in an afternoon, and monitoring the head temps so it doesn't get too hot.

Sounds like 1000 miles of lurching, spitting, chuffing black smoke, and contaminating the oil with gas is the easiest of the two.(????)

Preparation

First, I started with a map for an engine with a 2-into-1 exhaust. There might be a chance that it would have some similarity with the requirements on this one.

Second, I went to the 'ECM Constants' and put in all the correct parameters, with the exception of the injector size. That, I put a little low. This has helped on previous calibrations, to keep the VE values below the software maximum. Upload that map to the ECU.

Third, adjust the A/F ratio map to 13.5% at all the cells.

Fourth, adjust a couple degrees out of the the top few rows of the ignition map. Big engines can have lots of compression, so I didn't want to take any chances. Bob had measured it at 10.5:1, so I felt that a couple degrees would be enough.

Fifth, adjust the idle up to 1100 RPM at 65 degrees C. (I didn't think about this until after I started the mapping, but the idle was a little unstable with the stock idle speed map, so this should be in the sequence 'next time'.)

Sixth, perform the throttle set-up as per my article on throttle set-up; 57mm Set-up

Surprisingly, the initial throttle angle requirement is very close to that on a much smaller engine. The friction/pumping losses at idle must be pretty similar on most H-D engines, or the increased engine size pulls a higher vacuum. At any rate the set-up procedure is close enough to not require any specification changes.

Mapping

I've found that mapping both cylinders is possible with the Dynojet A/F ratio meter (it's actually an oxygen sensor but that's a story in itself) by using a long probe, inserted through the muffler, and a reasonable distance up stream in the pipe of the intended cylinder. You can confirm the correct cylinder placement by pulling a sparkplug lead on that cylinder. The oxygen sensor will indicate an extremely lean mixture because the oxygen level rises when the cylinder doesn't fire.

I started the engine having warmed it up setting the initial throttle angle, the front cylinder idle mixture needed a little adjustment. The first change to the front cylinder map didn't seem to give the expected response. The second change didn't either?

Guess what? The injector plugs were installed on the wrong injectors. I was reading the front cylinder and changing the rear.

After I swapped the injector wiring the low end mapping continued by changing both front and rear cylinder maps by roughly the same amount, even though I was monitoring one cylinder.

Then I started to map the 2% throttle position, by revving in neutral. Then the 5% position in 3rd gear, and up to the 10%, 20%, and 40% TP in 4th gear. All the while making similar changes on both cylinder maps.

Next, I switched to the rear cylinder to confirm and/or adjust each throttle position to get a flat, 13.5:1 A/F ratio chart.

Initially, I messed with the injector size putting the value pretty small, down in the 5.3 g/sec. range, but the VE levels were quite low. There's a trade-off between hitting the max VE values (unable to get enough fuel in that cell) and not having good resolution

On previous bikes I have tried changing the displacement value in the ECM Constants map, but it didn't seem to result in the the changes I needed, which was to lower the VE requirements. I have to assume that the displacement value doesn't have much effect on injector time, even though I had thought that it would.

Rather than pursue that avenue, I lowered the injector flow value and that immediately made the whole map richer. Since then I have used injector flow rating to give myself more VE adjustment.

After a few adjustments it looked like the VE values in the 40% throttle range were pretty low, so I went back and adjusted the injector flow to 6.0 g/sec. That was no problem because I had to heat cycle the bike a bunch of times anyway.

At the end of the first afternoon, I ventured a full throttle pull, and was pleasantly surprised.

The WOT A/F ratio was pretty flat, but I hadn't changed the A/F ratio map yet so it was still 13.5:1 and the timing wasn't optimized.

I monitor the engine conditions using the Race Tuner Data Mode program, so I know that the head temp didn't get about 105 degrees C for the first 4 hours in the dyno cell. As far as that goes, it didn't exceed that for the entire mapping process. I did notice that the cylinder head temps increase significantly faster than that of a 100HP 95CI engine, but there's no mystery in that.

Our well designed dyno cell gets the credit for keeping the engine temps under control, and it allows me to work in there for hours on end without killing myself. Keeping the engines from overheating is obvious, but being able to spend lots of time in the dyno cell, is the means with which I've accumulated a lot of experience, and that is necessary to figure out this process.

Once I had 13.5:1 A/F ratios for both cylinders and all throttle positions and RPM (OK, not 'all' RPMs, but WOT at 750 RPM and 0 throttle a 6500 RPM aren't very important) I adjusted the A/F ratio map to 13.0:1 at 100kPa and one tenth of a ratio leaner at each lower MAP value (13.1:1 @ 90kPa, 13.2:1 @ 80kPa. etc.) but not quite as lean as the stock A/F maps.

It appears that the RT A/F calculations don't track perfectly with the Dynojet A/F ratio meter, and I don't agree that these engines need (or even, like) ultra rich A/F values at any RPMs. I think it's the manufacturer trying to create a 'safe' calibration by making it too rich on the top. (They might as well, they don't make much power up there anyway!)

Flash-load the newly changed A/F ratio map along with enabling the anti-knock and then perform a final check for anti-knock activity. The Race Tuner manual suggests good technique for this process, so that's the procedure I use.

An opinion about the anti-knock system and timing adjustment.

I figure if you're going to optimize the ignition mapping for power, you might as well set it for power at a lower engine temp.

I find the best timing with the cylinder head temp below 100 C. Reason? If you want to make power the engine has to be cooler anyway. Why retard the timing to protect an overheated engine? You have an anti-knock system that does that for you.

When I check the anti-knock characteristics I test at a cylinder head temp just over 100C. With the right anti-knock calibration (each RT map has it's own specifically designed anti-knock calibration) you can usually get by with no anti-knock activity with best power timing and head temp. just above 100C.

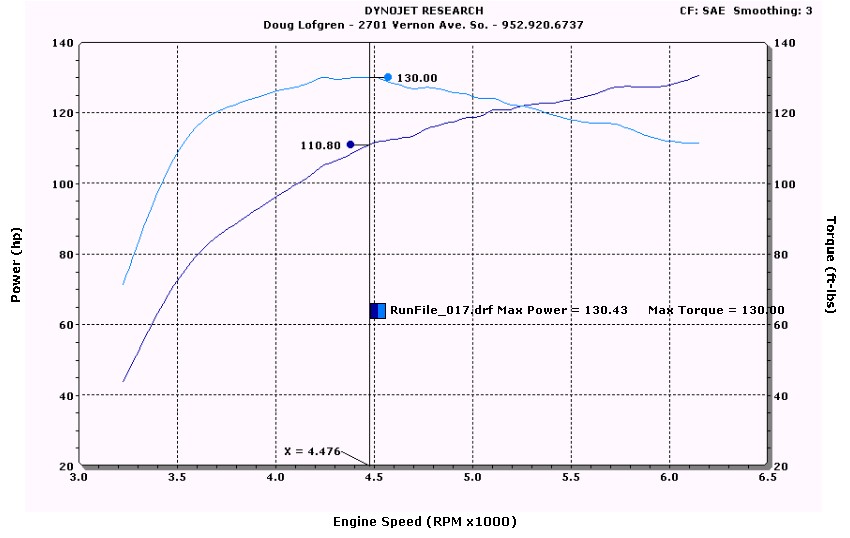

The final run in 4th gear is shown below.

Now is a good time to take a look at the difference that a higher gear and different correction factor can make.

Greg's bike has a lower overall gear ratio because of the lower primary ratio that came with the new heavy duty clutch (it might have been a communication SNAFU, but it doesn't matter) so the top speed is 150 mph at a little over 6500 RPM in top gear.

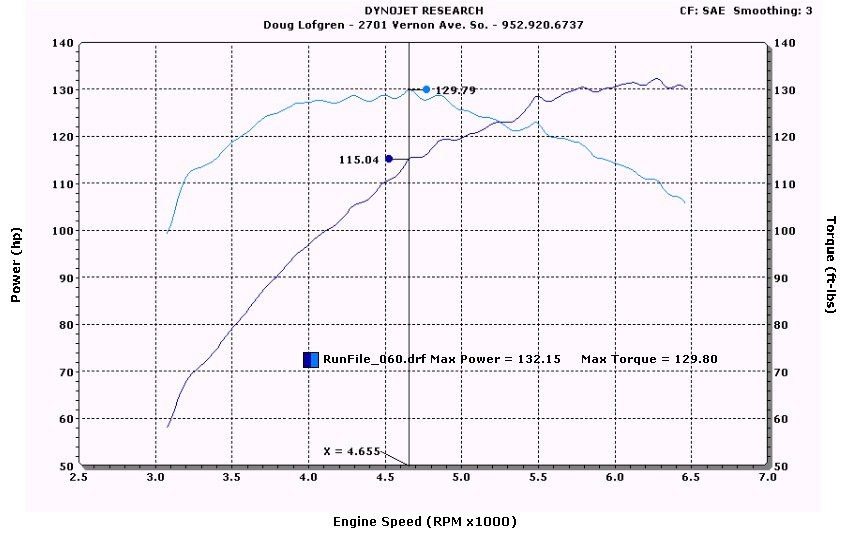

The chart below compares the previous 4th gear run with a 5th gear run, both with a more favorable correction factor.

As you can see, it turns a 132 HP bike into a 142 HP bike. All of that's just fine as long as you're using the same gear ratio and correction factor as a reference.

With Greg's bike being geared so low, considering the rate that it accelerates in top gear, the power would indicate even higher numbers with higher (higher top speed, lower numerical) gearing.

Conclusion

In spite of the fact that Greg expected me to do this calibration, and knows that I have a good reputation, there was still some doubt whether somebody local (Minnesota) could do this kind of job.

When you have a unique, unknown engine build, you need to have someone who can learn, because the person who already knows, doesn't exist.

The bike is quite drivable in spite of the rather long cam timing needed for the relatively small ports. It is a little lumpy below 3000 RPM, although it pulls just fine below that.

Everyone who has ridden it is impressed with the drivability. That is exactly what I expected since I've created maps for a bunch of odd-ball combinations, some of which I've designed/built myself.

I've distilled this whole mapping thing down to a 'process' rather than 'stab in the dark', it's a challenge not a nightmare. Now there's no frustration involved, just results.

I've learned that a lot of really built-up engines run badly because they weren't properly tuned rather than because of 'the pipe' or 'the cams' or any other excuse somebody has given rather than learn how to tune engines.

Since I've learned how to create fuel and timing maps, I've learned a lot more about each engines I build or tune. Only when the fuel and timing are right everywhere, can you begin to understand anything about the parts you've put into the build.