Joe Lee's 872 Ducati

Joe had his 748 built by Bruce. He used 996SPS cams, stock valves, and I assume, flat-top 95mm Pistal pistons. The bike has an EVR big air-box and I'm not sure what velocity stacks are used. I think Joe said that the air-box needed shorter stacks.

The exhaust system is a 45/50mm Arrow 1/2 system.

Joe has been very pleased with the bike but he was thinking about changing to the Akropovic 45/60mm system.

Here's where the 'managing your customer's expectations' comes in. Joe had read a bunch of my tech reports, among them the one where I showed the comparison between Milcheck's and Conway's as they came into the shop. Joe thought that the Akropovic would gain 6HP all by itself. The variation of one 748R to another is huge, largely because of the horse-shit inlet ports. My personal conclusion about the Akro was that it probably gained a few right at the top.

Anyway, Joe and I had talked about testing and optimizing the maps of the Arrow 1/2 system and then installing the Akro and doing the same.

After a thorough warm-up, the WOT performance was quite good.

It's difficult to improve on good work. As you can see the WOT A/F ratio is very good.

My only choice was to fix the rich swing at 5000RPM and try some timing changes. It turns out that this particular engine with this particular fuel likes a little less timing. I took out 2 degrees at the top, then 2 more.

OK, that's good, now change the pipe.

I share the shop space with Bob Wright, who's customers are Harley guys. He invited one of them into the dyno cell to see a bike that revs twice as high as his Harley. On the way out, he asked the guy to guess how much the Akropovic costs. The first guess was (in an expensive tone of voice) '$600?' I just laughed.

I installed the Akro and went home. This morning I warmed it up and gave it a shot.

There it is. Almost 3.5HP better at the peak. I was concerned that the small ports might dilute the advantage of the pipe at the top, but it works.

Joe was disappointed, again because he had expected it to be way better everywhere. I said that it is an excellent pipe because it doesn't make less anywhere and makes more at the top.

The dyno cell is a paint booth and the ventilation system has the capability of pre-heating the inlet air. Unfortunately, the heater is like a 'rosebud' torch tip and it just burns in the air stream. I thought I'd try to use it this morning because the outside air temp was 15F. Actually, it was the first test with the Akro and I wasreally shocked. It wasn't 'til I turned the heater off and re-checked it that I found out that the Akro didn't put it 'in the ditch.'

Here's what I saw after the 'heated' run (red.) This is compared with the run from the evening before (blue.) Ouch!!

Turn off the heat (oxygen depletion system) and lo and behold, the power comes back. Although the inlet temps as measured at the Dynojet 'stack' are only 6 degrees apart, the actual inlet temp at the air conveyors is more like 20 degrees. This represents 2% of the difference, but the rest is attributable to the oxygen consumed by the flame. You will notice very little difference in the A/F ratio portion of the chart.

Finally, a comparison of Joe's with an 853/748SP. They both have the same combustion chamber, and the same pistons crown shape (what shape?, it's flat!), so Joe's has a little higher compression ratio by virtue of it's larger bore. The 853 has 748SPS cams which are a little less lift (10mm vs. 10.25mm) but the 748SPS cams, both inlet and exhaust, have considerably longer duration. The 853 engine has big valves, 35mm vs. 33mm inlet and 30mm vs. 29mm exhaust, and a 50mm Termignoni system.

I think that the extra duration of the 748SPS cams (blue) cause the loss of torque at lower RPM. This isn't from inlet closing timing either, because all of the Ducati inlet cams close around 70 degrees ABDC. I think the loss of torque is from too much overlap.

The torque with the 748SPS cams climbs steeply compared that of the 996SPS cams. This looks like a genuine case of poor low speed torque.

There is one other problem with the 'other' engine. The torque curve needs to be shifted. Notice the dip at 10,000RPM, then it starts to recover just in time to hit the limiter (which is 800RPM higher than the limiter on Joe's.) Since it has stock 50mm throttle bodies and velocity stacks I don't know why the torque tunes so differently from Joe's. The larger pipe will tune at a higher RPM, the tapered Akro pipe should act shorter, instead it seems like it's tuning longer (lower frequency.)

The 853 might respond to longer inlet or a small restriction at the outlet of the muffler. But, it had to go.

Joe decided to use the Arrow/stock system and put the value into larger valves.

Late breaking news!!! He changed his mind, and decided to get greedy with the HP.

I think the engine should like larger valves because of the shorter inlet cam. As it is, this engine is making brilliant torque and power for it's size. Although I believe it should like larger valves, it's hard for me to expect better performance than it already has.

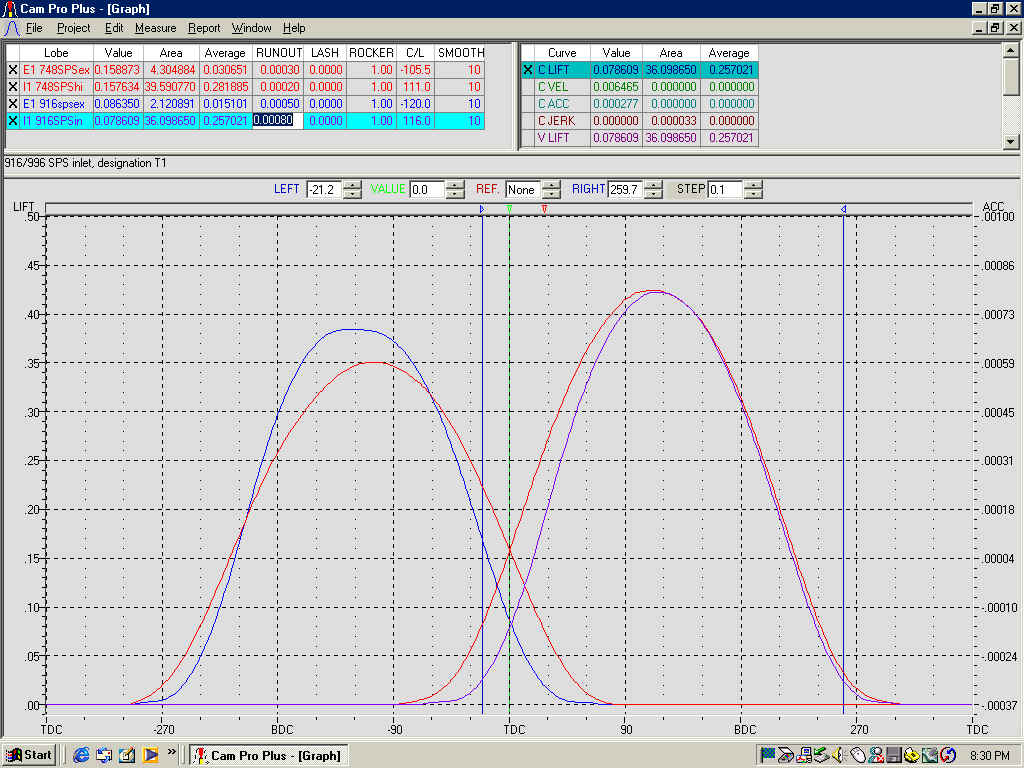

I decided to look at the cam charts (might as well, since it's easy) and the result is below. The red traces are the 748SPS cams and the blue are the 996 SPS.

The early opening of the 748SPS exhaust probably supports higher RPM but the overlap is nearly 4 times the valve area and twice the time. The power of Joe's engine implies that the 996SPS cams have enough overlap to clear the cylinder up to the power peak.

The 853 with 748SPS cams has just a little less than proportional torque, so it appears that the excessive overlap doesn't screw the torque completely. The combination of weak lower RPM torque and higher HP peak makes one wonder why one would prefer that kind of torque curve.

The excessive overlap thing appears to have similar negative effects on the Harleys. I have yet to collect the cam profiles of any H-D cams, so I'd better get busy.