A Basic Hop-up

This article is about an H-D Twin cam engine with stock heads and 'drop-in' cams.

This could get long.

A little history

I've been lurking and participating on the HTT (Harley Tech Talk) MSN forum for nearly a year.

There are only two areas that I feel qualified to comment on, tuning, and cams.

I've stayed out of the cam discussion because I know my opinions are contrary to 'conventional wisdom', and because Mike Roland is already answering the questions.

I work for Kuryakyn but I'm not professionally invested in the Wild Things cams. Intellectually, I am invested. Roland and I started this cam conversation more than 10 years ago.

Basically, the conversation started with my claim that Harleys operate under the same laws of physics as every other engine. Mike reminded me that there is one area that differs from most other engines (Chevys included) and that is the inlet system design. Furthermore, (to respond to my insistence that over-square engines can, in fact, produce equal torque) the parts weren't available to confirm this theory.

Of course, he was right on both counts, but after that time the parts started to become available. I'm talking about the larger bores.

After a couple years during which we met only infrequently, he told me that in that entire time, he had not had one other knowledgeable engine person that agreed with my perspective. He didn't say that to change my mind, not intellectual intimidation, but rather out of amazement that so many experts where so invested in the 'conventional wisdom'. (More about the Harley culture in some other document.)

I think that realization challenged him because that's when we started to design the Pro-stock engine. That engine took shape on the computer (using Dynomation) because the parts weren't available at that time. Eventually, we used the ports from his Top-fuel heads (the Shumaker ones) to model the ports for the Pro-stock engine.

The computer model showed that the Pro-stock engine liked wider lobe centers while my cam data from every other engine (I had no Chevy data) confirmed that. At that time we assumed that the narrow lobe centers, so prevalent in the Harley and Chevy/Ford worlds, were necessary for the 'Y' manifold.

Around this time Mike sold his beautiful 1948 (the first year for that model) Pan head and sidecar and bought a Buell S2. We couldn't afford to build the Pro-stock engine (S&S did have the cases for that project, but we couldn't get George Smith take part in that) so Mike decided to build the separate inlet Buell engine as a 'proof of concept'.

I donated over 250 dyno runs to that project (that's why I say I'm 'invested') and the results can be read on this homepage. Long story short; it made plenty of torque and HP too.

The Buell used wider lobe centers and shorter duration on the exhaust cam and we assumed that the good result was due, primarily, to the inlet tuning offered by the separate 13.5" inlet length.

At some point, and the reason for this evades me, Mike assembled his Buell engine using the 'Y' manifold but left the wide lobe center cams in it.

When we tuned the bike, it was just a little bit low on torque, but had excellent power. (Sound familiar?)

Around that time Mike had Andrews make some Twin-cam cams for him, those were the TW11Gs that are now the TC4G.

Cam Theory

In the late '80s I hung out at Induction Research, an engine/cylinder head shop owned by Steve Vermeer.

While hanging out there, I was introduced to two computer programs, Engine Expert, by Alan Lockheed, and Controlled Induction, by Rick Jones.

Engine Expert is an excellent program for determining and understanding engine dimensions, and Controlled Induction is intended to determine cam requirements.

From Steve Vermeer, I learned what the 'Chevy' guys think about cams and port flow. Namely, the importance of the intake-to-exhaust flow relationships.

There was only one problem, the CBR600f2 that we were racing had way too much exhaust flow according to the 'conventional wisdom'. The exhaust flow was higher than 90% of the inlet flow at some of the lower Lift-Diameter ratios.

Steve made a point of pushing me on why I allowed that, and I didn't have an answer. I knew that the engines loved it, but didn't know why.

Since then I've come to some conclusions on the subject.

There are huge fundamental differences between the function of intake and exhaust ports.

First, the inlet port needs to flow the greatest amount of air around the point of maximum piston velocity. That is between 72 and 80 degrees ATDC, depending on the rod-to-stroke ratio. That means that the inlet ports have to work the best around the highest valve lift range, which is around the Lobe Center value. Fortunately, even though the max lift happens after the max piston velocity, that does occur in a high valve lift area.

Furthermore, as the RPM increases, the cylinder pressure depression rate on the inlet stroke, increases. This tends to increase the port flow. Of course, the port flow velocities and accelerations increase too, causing losses, but at least the two factors work to cancel each other rather than both working to screw the performance.

The exhaust flow is a different animal altogether. It is fairly well accepted that 1/2 of the exhaust mass should exit the cylinder by BDC. If not exactly 1/2, at least a significant amount.

Since the piston is dropping between E.V.O (exhaust valve opening) and BDC, the piston doesn't help to push it out. During this part of the cycle, the high initial pressure (that's the powerful exhaust note we all love) and good low lift flows are the only factors that work to clear the exhaust gases.

By the time the piston is rising, the pressure is low and/or dropping and the exhaust gas density is low (low mass) so pumping doesn't help much when the exhaust valve is at it's highest lifts.

As the piston approaches TDC at the right RPM range, the exhaust pipe pulses go to work (if you've done your exhaust system development properly) to extract the last bit of residual exhaust charge and jump start the inlet charge. Again, the flow at low lifts is important because the exhaust valve is closing at TDC.

Unlike the case with the inlet side, where increased RPM creates some benefit for the process, the exhaust merely has a shorter amount of time from EVO to BDC.

Double the RPM, halve the time. That's why the exhaust opening has to be advanced for higher RPMs.

Since you still need to have the exhaust valve open the same amount or longer after TDC, the exhaust duration needs to be longer for higher RPM engines. Or, the exhaust valve has to be larger, or the low lift exhaust/intake flow ratios have to be higher, or all of the above.

There's one other geometric fact that applies to this subject. The valve curtain area (that area which is a cylinder, with the diameter of the valve head and the length equal to the lift) is equal to the area of the valve head at a lift-to-diameter (L/D) ratio of .25. That's simple, the area of a cylinder is the circumference of a circle (pi time the diameter) times the length of the cylinder (valve lift.)

The area of a circle is pi times the radius of the circle, squared. Since the radius is 1/2 the diameter, that value is always .25 times the diameter.

Pi X the diameter X .25 gives the same result as pi X the radius squared.

In reality, ports don't behave exactly like that for a variety of reasons, but basically that describes the relationship between lift and valve size.

The pre-Testastretta 4V Ducati Superbike cams confirm this view. Ducati used the same exhaust cam from 1993 until 1999. The engines went from 135HP at 11,000 RPM to 190HP at 12,500 RPM.

The valve sizes got larger through that time period, so the low lift exhaust flows increased while the max L/D of the exhaust decreased., obviously supporting the increased power and RPM.

In 1993 with the 'G' cams, the valves were close to colliding, so the inlet duration began to get shorter (on the opening side only, thereby retarding the Lobe Center numbers) while the lift got higher. This allowed larger inlet and exhaust valves and the power increased as the valves got bigger. As the inlet valve grew in size, they could shorten the duration, which kinda confirms that thing about RPMs and piston speed helping the inlet flow.

What the hell is he rambling about?

If the exhaust valve needs good low lift flow more than the inlet valve, and, the exhaust valve is smaller than the inlet valve (needing proportionally lower lift than the inlet valve), and, the large displacement 45 degree V-twin is a low RPM engine, why do so many cams have more lift and duration on the exhaust lobe?

My theory? If you are building a race engine with well seasoned (read, used) school bus parts from a junk yard, and you intend to rev it higher than the the 2800 RPM that the school bus ever used. You will need a cam with more exhaust lift, duration, and/or valve size than the one that came in it. The cam maker had many lobe templates, so he added one with longer duration which also had higher lift, oh well.

Take a look at the cam maker's catalogues. They are filled with cams with the same or more lift and duration on the exhaust side as that on the inlet side.

Keep in mind that American cam manufacturers have had a long and profitable relationship with American V-8 tuners. The Chevy V-8 is undoubtedly the most highly developed racing engine of all time, so it's not surprising that the influence is strong.

There are always a number of different ways to tune so it isn't surprising that American V-8 tuners use different techniques than other folks. Rather than adjust the exhaust cam lobe, they have increased the inlet to exhaust valve size relationship.

Mike Roland and Ed have both mentioned that there are examples of engines which don't have the same lobe dimensions on the exhaust as on the inlet. In fact, most engines (other than American V-8s) have cam relationships that use less lift and duration for the exhaust along with higher exhaust-to-inlet flow relationships.

Tuning

It has been implied and stated on the HTT forum that tuning is cheating.

I have to ask; if you've paid $3000 for engine work and the engine is 10HP short of what it should be, are you getting your moneys worth?

How can there be any upside to an engine running at less than it's maximum efficiency?

The A/F ratio may be too rich or too lean. The timing can be too advanced or too retarded. How can that be any good for your engine?

Once it's tuned, if you don't need the HP, don't open the throttle! At least it's running right.

OK, forget the conversation about getting your moneys worth from the engine build.

As a performance engine builder I had to tune the engines in order to determine what, if anything, the parts had contributed to the result?

Does it run like crap because the carb is no good or is it that the main-jet is wrong? Or is it the timing, or the pipe, or the cam?

You can spend a day on the dyno and get it 90% tuned or you can trailer your bike all over the country for half the racing season to get to the same point.

How many times do I have to say it?

The Bike

Mikes long time friend, Scott Point, owns a 2003 Road Glide with a Screamin' Eagle air cleaner and V&H Pro-pipe. First, he put a TC1 cam in it with a TFI box, and was pleased with the results. Scott lived in Montana at the time and there was no opportunity for us to tune it.

Then Scott wanted to step it up a notch, so he put a TC2G in it, along with thin head gaskets. For this stage, he bought a S-E EFI Race Tuner Kit and Mike fudged together a map based on one of the Kuryakyn bikes that we had done. The bike ran well, but had some part load issues, assumed to be richness.

Scott moved back to Sioux Falls SD (that's where Mike grew up) and the last time Mike went home, he brought Scott's bike back to the shop. They had cooked up a scheme to tune it (to have a good map for 88s with that combination), then install 95CI pistons and tune it again.

We have known all along that the cranking compression was pretty low with the Wild Things cams, and we have considered trying to bump the compression a little for any application so Mike decided to install the new 10.5:1 pistons to see if it could handle the extra compression.

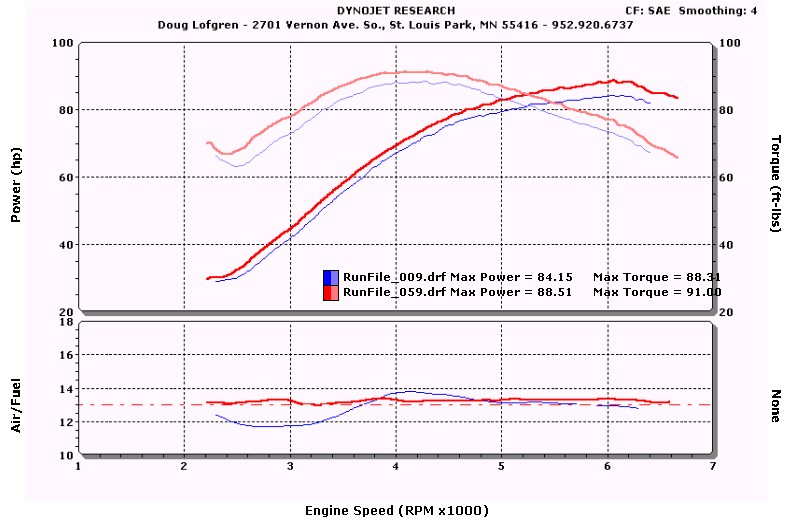

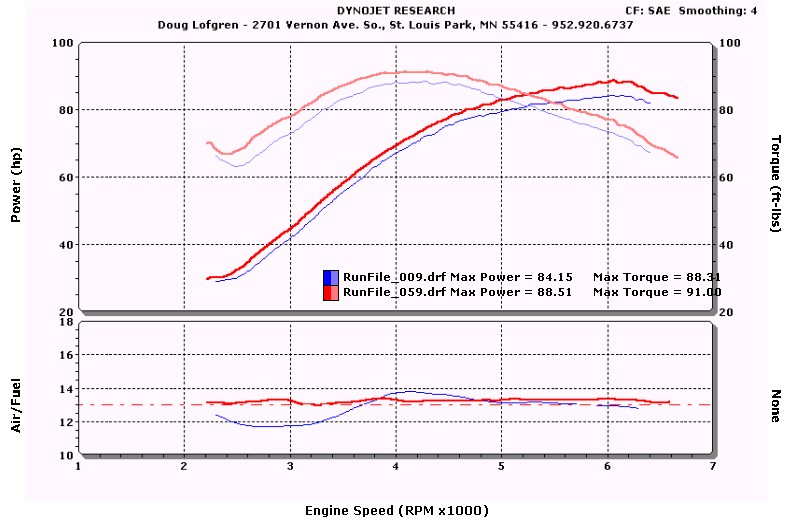

I put the bike on the dyno for a baseline, then created the correct map. The engine responded to fuel corrections as well as timing changes. Below is a before and after of the 88CI bike with stock heads, stock pistons, TC2 G cams, Cometic head gaskets, V&H Pro-pipe and S-E air cleaner.

Notice the relatively flat A/F ratio.

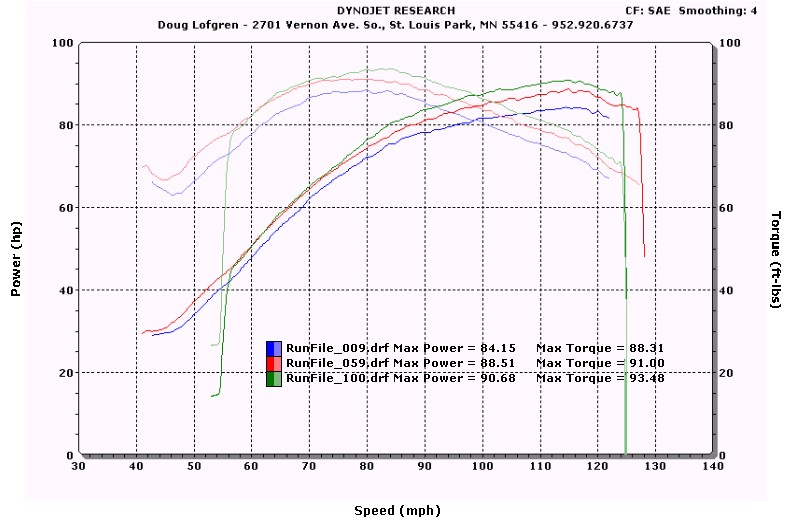

Later, we pounded the bike some more to test some new products and a Hyper-Pro air cleaner. We didn't expect to see any improvement but surprisingly it gained some more.

Below is a graph with the previous two runs and the later run in green.

I test rode the bike and the drivability was excellent. So we now have a really good map for that combination.

Next I gave the bike to Bob Wright of R&D Performance, with whom we share the building. (Convenient huh?)

Bob had prepared a set of cylinders, so it went together in a day and I put it back on the dyno.

I changed the displacement on the ECU Constants page of the Race Tuner calibration file and uploaded it to the bike. I'm not sure just how much that should respond, but the map was pretty good. It was a little lean, but I had a good map in a couple hours.

Compression

We checked the cranking compression at this point. The engine was warm (it had been run just before lunch, we checked it after lunch) and the cranking compression was 180 PSI.

Back To Testing

Apparently Scott had expressed an interest in a Hyper-pro, so we installed one to confirm the earlier improvement that we saw when it was an 88.

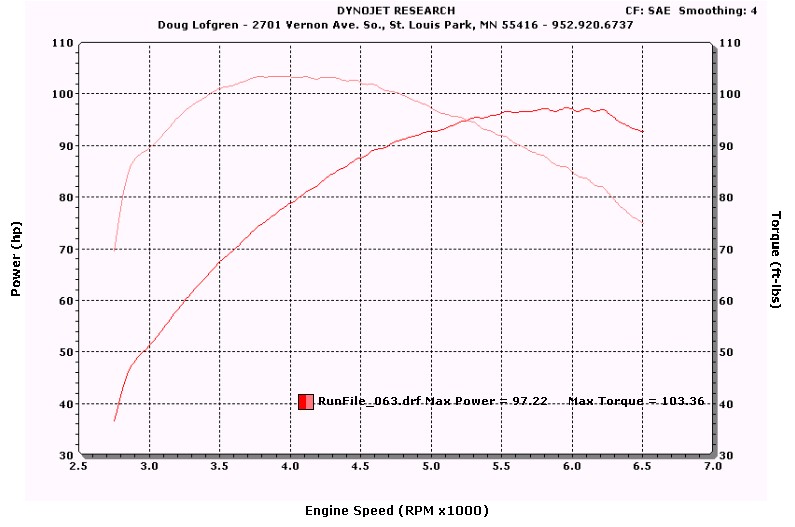

The result with the Hyper-pro, 10.5:1 pistons, stock heads, stock head gaskets (the Kuryakyn pistons are 0.015" taller than stock, so they don't need thin head gaskets) and V&H Pro-pipe is below.

At this point we're regretting that we didn't put the heads on the flow bench when they were off the bike. We didn't, so we don't know just how good they are.

Since we had seen 90HP from the '03 Kuryakyn Deuce with the same cams, we have no reason to suspect that the heads are significantly better than any others.

As close as it was to the magic100HP line, I took a look at the pipe testing I had done on Bob's bike and confirmed that the Bassani Power Curve true duals were worth a couple HP. At least they were, at the 90HP level!

I couldn't help myself, I had to install the Bassani system!

It required some map adjustment, especially to the rear cylinder. The rear cylinder pipe on the Bassani system is intended to be equal to the length of the front pipe, so the map should be different than the map for the rear cylinder with the Pro-pipe.

It responded almost like I had hoped but it was still a little short. Then I looked at the Data Mode file and noticed a little bit of anti-knock activity.

I disabled the anti-knock and made a slight adjustment to the rear cylinder map (where it had shown up to 2 degrees of anti-knock) and finally added about 1/2 degree at the top of the map.

I had noticed that the runs in the 70C cylinder head temp range weren't quite as good as those in the 80C range, so I did a 5th gear run first, then started the 4th gear run at 82C.

Bingo!

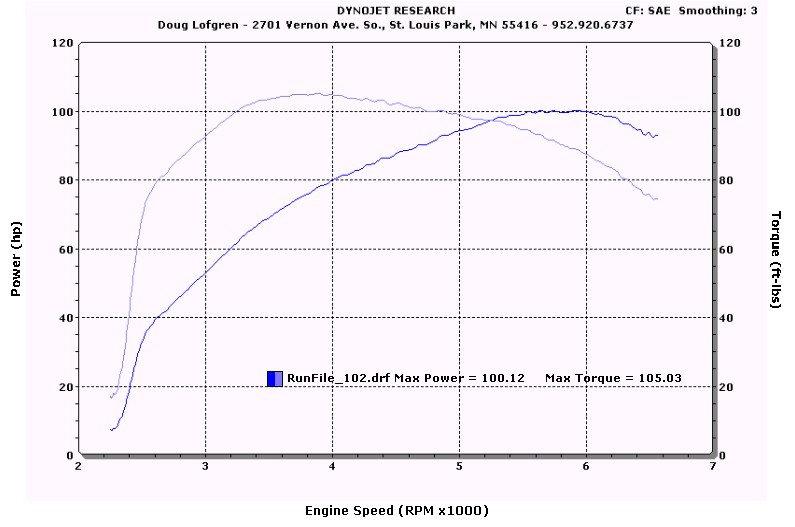

That is a 4th gear run using the SAE correction.

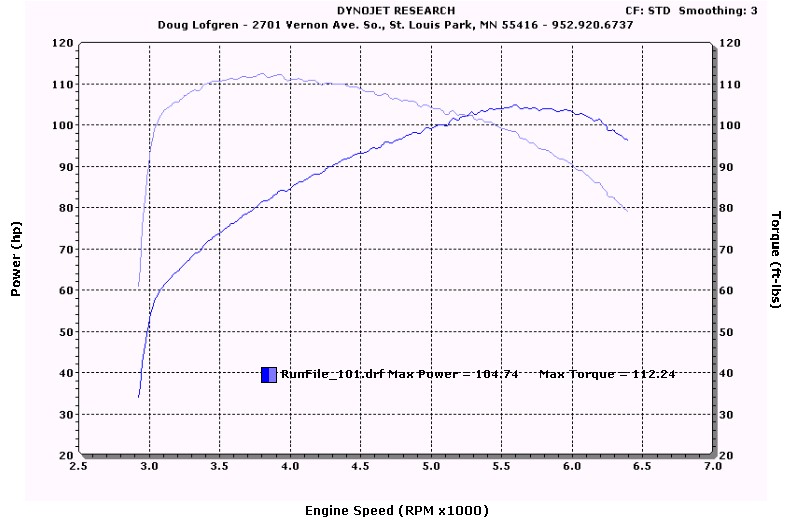

If you like using 5th gear and the STD correction, check out the run below.

On the subject of tuning? I rest my case!