An 872cc Exercise

The response, so far;

Apparently, quite a few people have read this report. There is a consistent thread of mis-understanding about the displacement.

This example is 872ccs because Gary supplied the pistons with the bike. At 95mm, there is a chance that the cylinder spigot can break off because it is borderline too thin.

Head gaskets are a real pain in the ass because they have to be made from 94mm gaskets. I don't like taking chances with head gaskets as Ducatis can have problems there.

So, I don't feel inclined to recommend the 95mm solution rather than the 94mm 853cc.

The performance of this engine comes from the compression, combustion chamber, and tuning, tuning, tuning. not from the magic number 8-7-2! Don't be surprised if we recommend going with the 853 kit, over the 872.

The original report

The 748R is the street version of the 748RS, which the FIM uses to homologate several specifications for World Supersport.

Those would be;

valve size and weight (material)

piston crown shape

valve lift (but not duration)

throttle size and injection configuration (this also includes an FIM restriction for twins)

Since Gary isn't competing in World Supersport most of this stuff doesn't matter. I defined several areas for improvement.

Goals

Gary claimed that he wanted to make some power and he wasn't too concerned about revving the engine to get it. Actually, the way he stated it was, that he wanted power and didn't care too much about torque. (Therein lies a common mis-conception about the requirement of giving up torque to make power.)

I already knew that the inlet ports were terrible and was aware of two other 853cc 748Rs. One of my goals was to make the finished product at least as efficient as the two bikes in question. Both of those made just under 122 HP.

I prefer to look at the torque-per-liter rather than power-per-liter. Displacement specific torque is a lay-persons BMEP, which is generally accepted as a valid measure for the comparison of different types of engines. Since my rear-wheel inertia dynamometer doesn't measure at the crankshaft, any actual crankshaft torque figures would be a guess anyway.

With an extra 2.23% displacement (872/853) I'd be looking at 63 lb ft of torque and 124 HP.

The bike should run on 92 Octane pump gas. The question is always; how much compression can I have and still use readily available fuel?

If at all possible, minimize the maximum RPM at which maximum power is produced. Valve train life is inversely related to peak operating RPM squared.

Pistons, Combustion Chamber, Compression

The bike was delivered with 95mm Pistal pistons purchased from BCM.

The Pistals have a flat top configured just like 916 Strada pistons. This is ideal for a stock 748 Strada combustion chamber, but the combustion chamber of the 748R is a little larger in volume than that of the Strada and compression would suffer further if the chamber is opened up to optimize the flow of the heads and the squish of a 95mm cylinder.

I measured the combustion chamber volume and could make an informed guess at the volume of the pistons, since I have measured several 853 and 916 pistons. The 872 pistons have the same crown configuration as the former.

I use a spreadsheet to calculate compression ratios, so I can easily model different combinations of pistons crowns, chamber volumes and gasket thicknesses.

I found that the stock 748R chamber and the flat-top pistons left me with a compression ratio in the mid 11:1 range.

That's fine, but what if I wanted to un-shroud the valves or adjust the squish configuration? In the ditch, that's what!

Well, I fixed that problem with the same solution that I used on Feldman's 748; Hi compression 748

This allowed me to open the combustion chamber and still retain some compression. I would have to machine the heads and the piston crowns to accomplish this.

Below is a photo of the near-finished piston crown. The valve cut-aways still have to be adjusted for the different valve centerlines.

After I had cut the seats and opened the chamber, and roughed the pistons crowns (see above) I calculated that I had a 13:1 compression ratio.

Gary was concerned about what type of gas it would need (he does ride it on the street at times.) After adjusting the valve heights (shim thickness) and the valve clearance pockets in the pistons, the final compression ratio was 12.38:1. Perfect for 92 octane.

Ports

In spite of the reputation of the 748R (mostly, they are hard to get) the inlet ports are really bad. That isn't to say they aren't too good, that is; they are BAD.

Ducati knows how to make a pretty good production port, so I was surprised at how poorly the 748R ports where executed. Because of the narrow valve spacing the port is a slightly different configuration from the Strada. For whatever reason the inlet port diameter is similar to that of the strada, then the large valve is seated and the transition on the floor side of the port is sharp step. I've been told that the RS inlet ports bear no resemblance to the R inlets.

The first big improvement would be to the inlet ports.

The exhaust ports are OK but the low lift flows could be better with a larger exhaust valve. Since the exhaust has to service a larger cylinder an increase of 1mm in exhaust valve size was in order.

Throttle Bodies

The throttle plates are 54mm but the restrictor area in the throttle bodies creates a lot of turbulence that continues way down the ports. Changing the shape of the throttle bodies would be part of the plan.

Because of the taper below the throttle blades, only one side of the throttle plate was exposed until approximately 20 degrees of opening. At first, I thought that might be a scheme to make the throttle action progressive, but finally decided to go ahead with the re-shaping on the premise that it was only the result of having to place the restriction somewhere in the port.

The whole thing is tuned to make power at 12,500 RPM, (that would be the 748RS) which means that the 'R' model doesn't see the RPM to utilize the dimensions.

Adjustments to the inlet dimensions had to be considered and tested.

Cams

The good news is that the 748R cams are pretty 'hot' in the lift category.

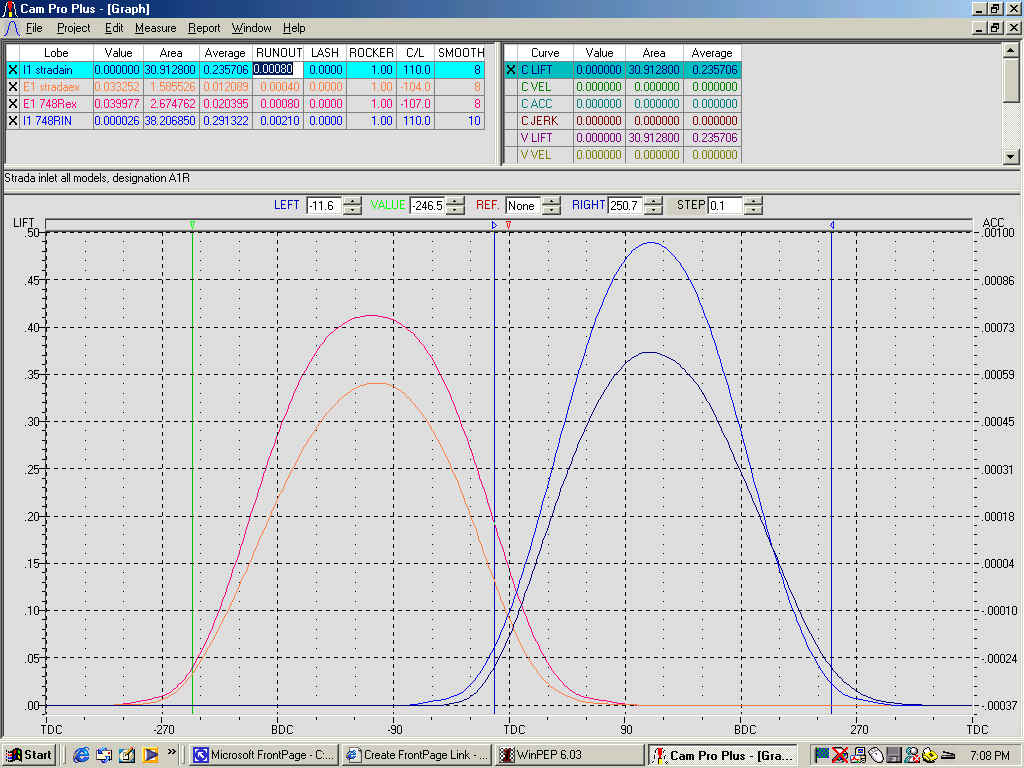

Following is a graph of the 'R' cams compared to Strada cams.

The intake has a lot more lift while the exhaust has both lift and duration increases. The extra exhaust is necessary to support the high RPM operation.

The customer was hoping for 130HP but there was no way I'd 'sign up' for that. There are two other 853cc 748Rs that I know of and they both made nearly 122HP, if I hit that specific power number (because of the increase in displacement that would be 124HP) I'd be happy, as well as in some pretty good company. I'd like to get that kind of efficiency.

Tuning

Once the engine is planned and executed it still has to be tuned. No-one has a 'chip' for this particular combination. Since I have the capability to re-map and burn new chips (and I have considerable experience in that area), calibrating the whole thing would be no different than any other day at work.

The combustion chamber and compression ratio changes mean that extensive ignition timing adjustments would be required. That would be critical since I wanted to make it run on 92 octane 'pump gas'.

Results

Finally, I've assembled the 'thing' (a tedious process at best) and synchronized the throttles (another tedious process.) It sounded OK on the bench, so it was time to roll it onto the dyno. The Ultimap chip that had worked on the stock 748R needed quite a bit more fuel because the power was pretty good. I took the 'Zone' changes out and burned a new chip that was more appropriate. I worked to a fairly flat air-fuel ratio and then took some timing out.

Since the bike is a street/track bike, I decided to try to make it run on 92 octane pump gas, so that's the way I'm proceeding.

The mapping isn't quite finished, and I have some other component testing to do. I don't expect it to make any more peak power, right now it makes 130 on every run. I'll be working to increase the torque and, maybe, move the power peak down just a little.

Right now, over 60 lb ft of torque from 6,700 to 11,4000 RPM is pretty good. The peak torque is about 77 lb ft per liter.

Following is a 'before and after' comparison.

The bike came with a 50mm Termignoni system, which, in most cases, would be plenty large but, with the results we're getting I have to wonder if it doesn't need a larger system. Take a look at the torque curve shift in the next graph.

You can see that the torque curve has shifted down nearly 600 RPM with the increase in flow.

In case anyone thinks this is just a 996, the following chart shows this 872 and a 996. 67 lb ft of torque would be a pretty sick 996.

The Next Phase

All the previous charts were generated early in this process. In spite of the good power numbers, the shape of the power curve is not optimized.

All of the power curves looked like the top end wasn't properly developed, so I needed to do some more testing.

I made some more changes and things started to improve, but the similar problems with the top of the power curve persisted.

The peak doesn't hold smoothly across the top, like I'm used to seeing. I'd have to try some other changes. In spite of the impressive numbers, I'd rather see several hundred RPM at 130 rather than that little glitch that goes to 131.9.

I made some restrictor for the outlet of the mufflers, hoping that I could cause the torque peaks to shift. I felt that the 50mm system would only act restricted if I did, but I did it anyway.

My suspicions were correct. As you can see it lost torque from the low torque peak all the way to the top.

The good news is that the torque peaks did shift a little and the top of the power curve has assumed a more pleasing form. That's what I'm looking for (and the fact that it's occurring below 11,000 RPM is a plus from the longevity/reliability standpoint) but I want the power back!

I fitted a 54mm Arrow system and started the whole mapping and testing process over again.

The larger system and several other changes have worked together to get that pleasing peak power curve and manage to make that pleasing 130+ number.

Rather than show one stellar power curve, I think a mess of them will show the pleasing shape of the final curve.

Inevitably, when you're making a lot of dyno runs, one run will have the best of all conditions. Hot oil (low power consumption from the oil pump) cool heads, and just the right air/fuel ratio. When you get that one run, it is bound to be the 'poster child'. Comparisons with other runs don't usually offer any insight, so you might as well just look at it.

This morning, while finishing the mapping for the big-pipe configuration, I stumbled upon that run.

It follows. The torque-per-liter is 79.36.

Now I have to go back to the 50mm Termignoni system and find the best combination and map for that, so Gary can ride it until he gets a 54mm system. I'll post that when I get it finished. There isn't a lot of power difference between the two configurations.

Below is a chart with three different configurations. Run # 50 (red) is the 54mm system, #19 (blue) is the 50mm system with the same inlet configuration, and #22 (green) is the 50mm system with a different inlet configuration.

Frankly, either #50 or #22 would be excellent, but I like the top power curve of #50. As you can see there isn't any difference in the torque, but it's made at different places. Ultimately, when you want to go fast you go to the place where the power is, and between 10,000 and 11,500 the 54mm system configuration would be what you want.

Finally I've finished the project. The last phase was finalizing a map for the 50mm system that Gary already owns.

For maximum power he would buy a 54mm system, but the 50mm Termignoni is working so well that it may not be a consideration.

The chart below shows the 54mm system (in red) and the 50mm Termi. With the torque shifted down a few hundred RPM you can see that the 50mm configuration offers 3 HP more at 9500 RPM. My guess would be that Gary isn't going to be in any hurry to spend a couple thousand more for those 2 extra HP.

Summary

The torque and power goals were exceeded.

The ability to use 'pump' gas was realized.

The tuning adjustments which increased torque, lowered the peak power RPM, thus realizing a lower peak operating RPM. This should help extend valve train life.